| Quantity | Unit price |

|---|---|

| To 2 |

£43.29*

|

| To 4 |

£40.63*

|

| From 5 |

£39.96*

|

No longer available

Master 112 Breather Membrane Roofing Felt from Easy-Trim

High vapour permeability and superior water resistant performance!

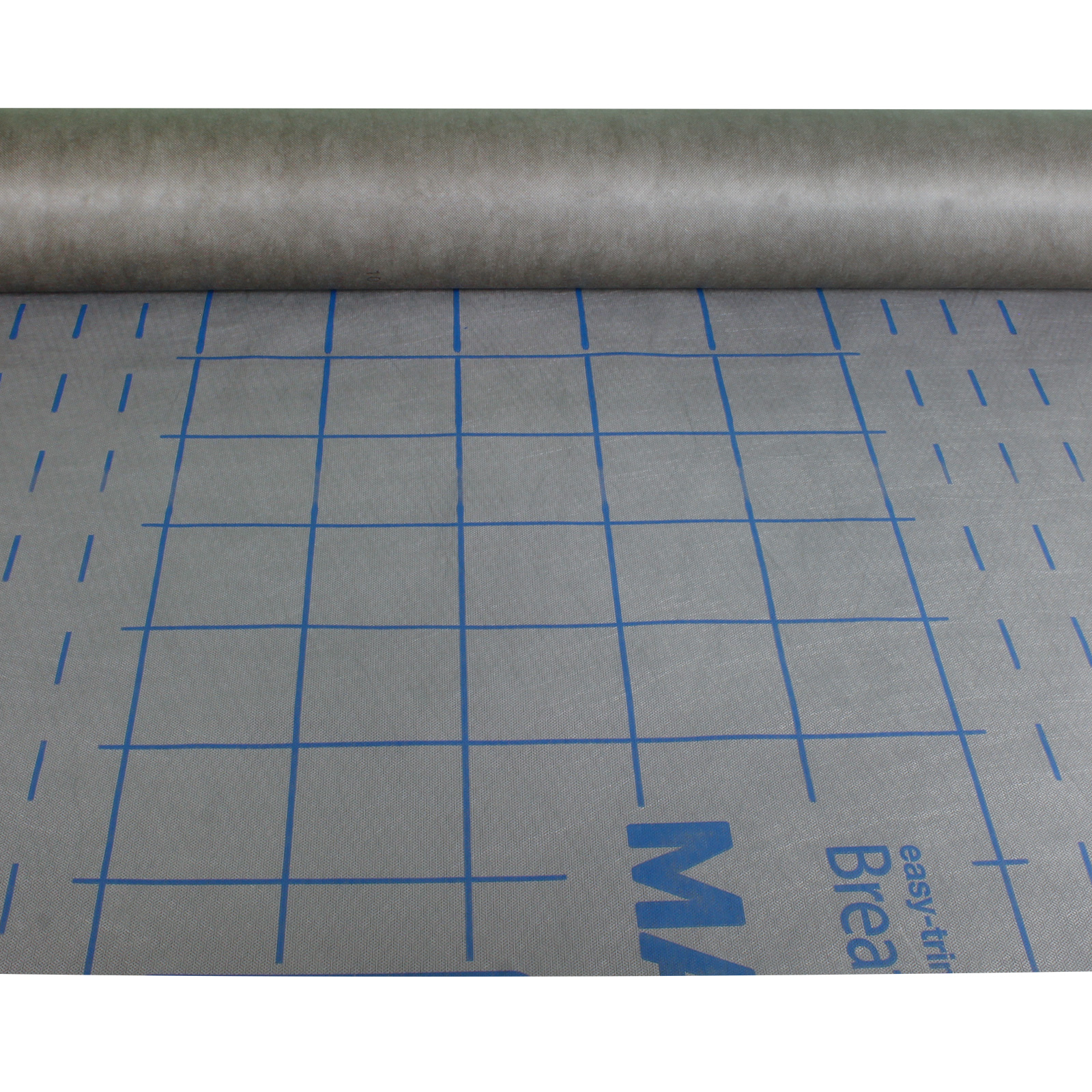

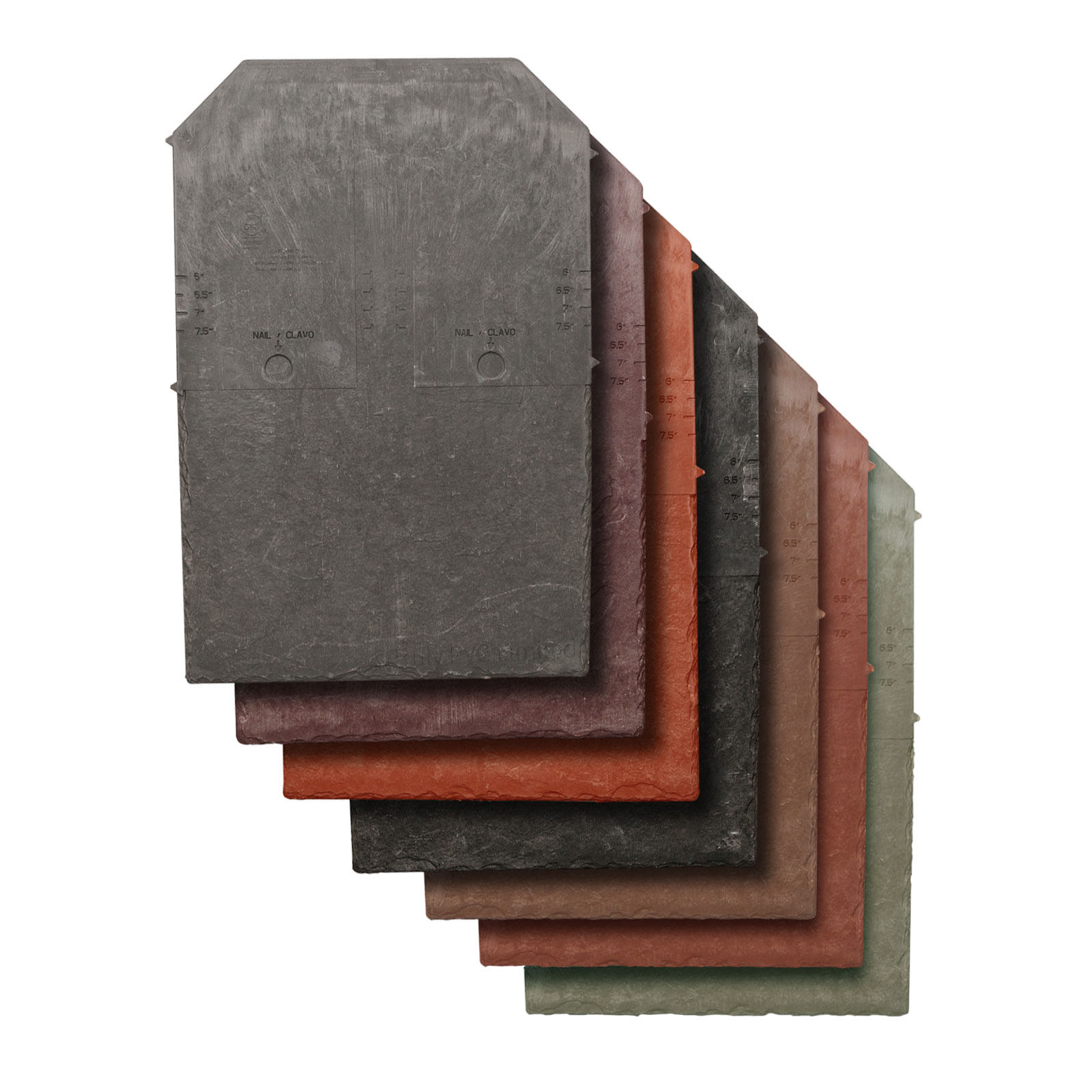

Lightweight and flexible 112gsm BBA certified roof underlay. Easy-Trim Master Breather Membrane offers good tensile tear strength and value for money. Suitable for both fully supported and unsupported installations in tiled or slate pitch roofs.

The Master 112 is a type LR (vapour-permeable) 3-layer micro porous breather membrane, which features a microporous film that is thermally bonded between two spun-bonded polypropylene layers. Allows the roof to breathe, so eliminates condensation, whilst providing secondary protection against rainwater ingress. Easy-Trim breather membranes improve energy efficiency and minimise the wind uplift that can loosen slates and tiles.

Features & Benefits

- Protects roof slate and tile - reduces wind uplift

- Reduces condensation in roof - highly vapour permeable

- Driven rain and snow protection - second line of defence

- Highly versatile - use on warm, cold and hybrid roofs

- Flexible yet strong - good tensile tear strength

- UV stable for 3 months - protection during construction

- Quality you can trust - independently tested

- Superior water resistance - protective polypropylene top layer

- Printed with brand and cutting grid - easier to identify and fit

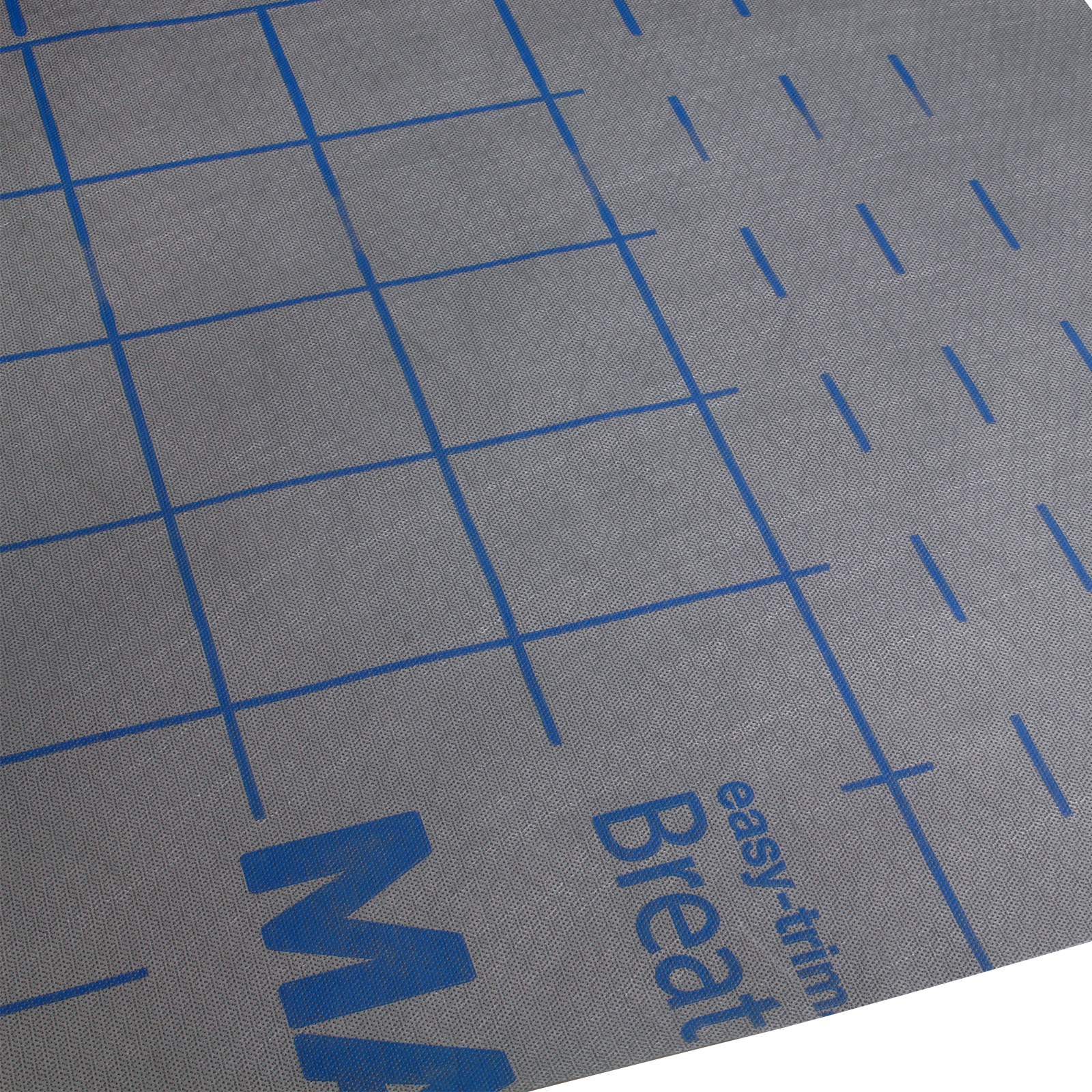

National Wind Zone Suitability

New builds must comply with British Standard for Tiling and Roofing (BS5534) Annex A, with breather membranes tested against wind uplift, and their suitability for use across the 5 national wind zones.

| Batten Gauge | Wind Zone Suitability | |||||

|---|---|---|---|---|---|---|

| Gauge | Lap | 1 | 2 | 3 | 4 | 5 |

| <=345mm | Batten | Y | Y | |||

| <=250mm | Batten | Y | Y | T | Y | Y |

| <=345mm | Taped | Y | Y | Y | Y | Y |

Technical Information

| Measurement | Performance |

|---|---|

| Material | 3-Layer Polypropylene Sheet (Spun Bonded Polypropylene Layer, Microporous Polypropylene Film, Spun Bonded Polypropylene Layer) |

| Mass | 112gsm |

| Size | 1m (3ft 3in) x 50m (164ft 1in) |

| Maximum tensile force MD / CMD (N/50mm) | 250 / 165 |

| Elongation MD / CMD (%) | 50 / 70 |

| Resistance to Tearing MD / CMD (N) | 115 / 135 |

| Resistance to penetration of air (m3/m2.h.100Pa) | < 0,02 |

| Fire Class | E |

| Water Resistance Class | W1 |

| Compatibility | Suitable for both fully supported and unsupported warm, cold and hybrid, tiled or slate pitch roofs. Can be used with sarking boards. |

| Certification | BS5534.2014 Annex A, Type LR Underlay to BS5250, BBA 10/4753, NSAI, CE |

Fitting and Usage

Fitting of Easy-Trim breather membrane should begin at the lowest level of the roof, at the eaves, with the printed side facing out. Starting from the left, roll the membrane horizontally across the rafters to the right, and be sure to allow 100mm lap over the felt-support trays. The use of double-sided overlap tape to secure the lower edge to the felt-support tray is highly recommended.

| Roof Pitch | Horizontal Laps | Vertical Laps | |

|---|---|---|---|

| Not Fully Supported | Fully Supported | ||

| 12.5 to 14° | 225 | 150 | 100 |

| 15 to 34° | 150 | 100 | 100 |

| 35 to 75° | 100 | 75 | 100 |

Horizontal laps in breather membrane should be taped with the double-sided overlap tape, or battened over. Whenever possible, horizontal laps should coincide with the closest tiling or slating batten. Vertical laps should be positioned over a rafter and have a minimum of 100mm lap.

Easy-Trim breather membranes are suitable for installations on all major pitch roofing and timber frame applications, and must be installed in accordance with our fixing instructions, complying with the recommendations of BS5534: 2014 + A1: 2015; BS5250: 2011 and BS8000-0: 2014 and any other applicable standard. The products are designed to be installed by competent and experienced installers of slates and tiles.

Login