Ridge F PLUS 'Dry Fix' Ridge/Hip Kit (6m)

(Available in Black or Terracotta)

NEW Ridge F PLUS is more streamlined and more secure!

Dry Fix F Plus forms a ridge that is resistant to water, whilst allowing the roof to breath. Offers quick and simple mechanical fixing of almost all ridge tiles, and guaranteed for 20 years.

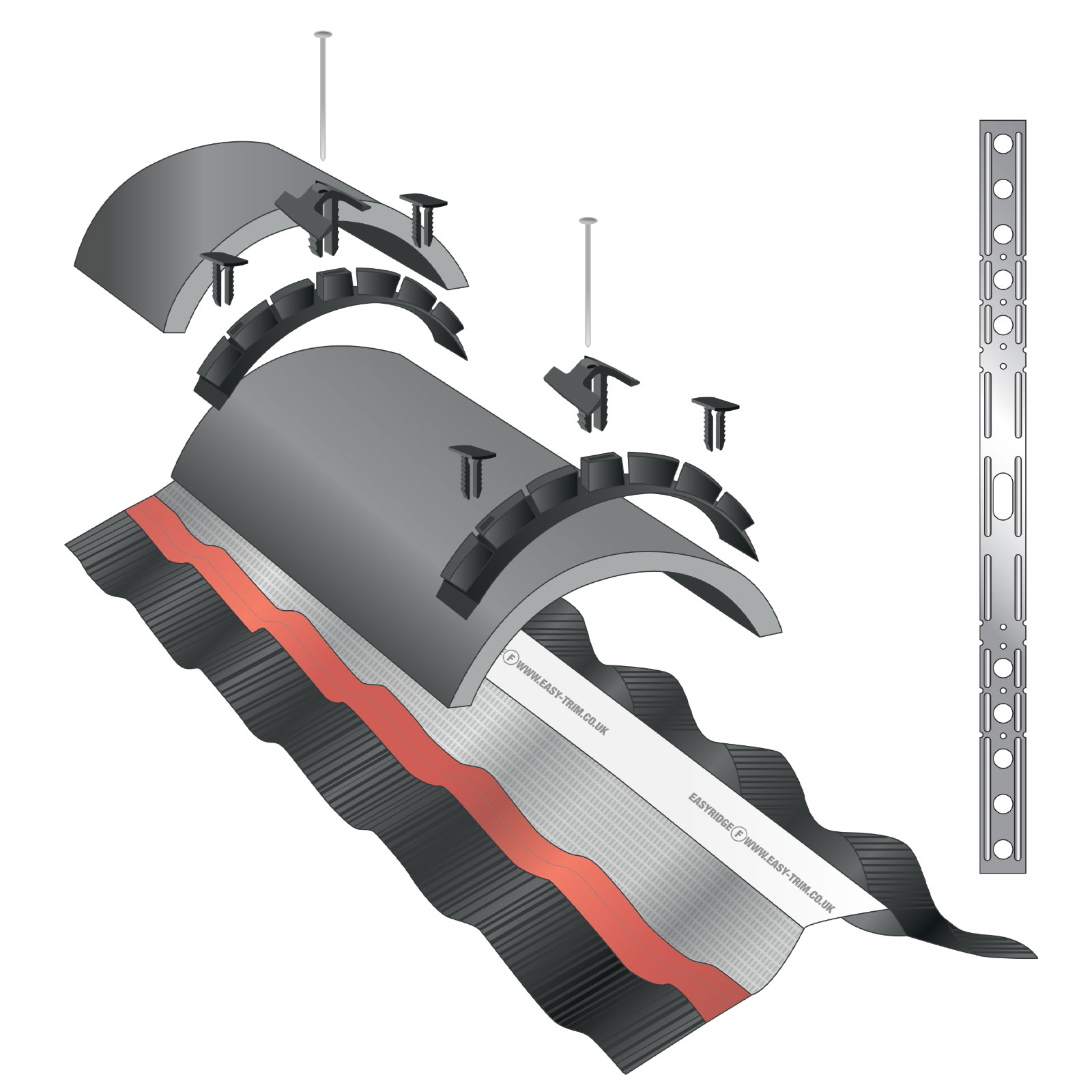

The ventilated Ridge Roll provides the equivalent of 5mm continuous airflow and it's malleable, crimped aluminium skirt with flexible ridge tile Unions are the key components that make this kit so effective. Together, they offer long term security with a quality water seal. Suitable for concrete, clay ridge tiles, and compatible with slate and tile profiles.

Features & Benefits

- Quick and easy to fit - no special tools or skills required

- Allows the roof to breath - provides a ventilated ridge

- Fully serviceable - easy to maintain even after many years

- Glass filled nylons - increased strength, resistance and stability

- Discreet design - provides a more streamlined appearance

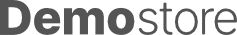

- Can also be used on hips - requires dedicated Hip Trays

- Long-life durable fixings - Stainless Steel and Nylon

- 20 year guarantee - British Standard product you can trust

The Easy Ridge F complies with BS 5250 and BS 5534 and is manufactured to DIN 4108/3. The dry fix system is resistant to freeze/thaw cycles plus thermal expansion/contraction and is recommended by NHBC.

CAN BE USED ON HIPS! Ridge F Plus is great on hips too! Just requires a dedicated Hip Try to be fitted over the ventilated roll (see our Hip Accessory Kits).

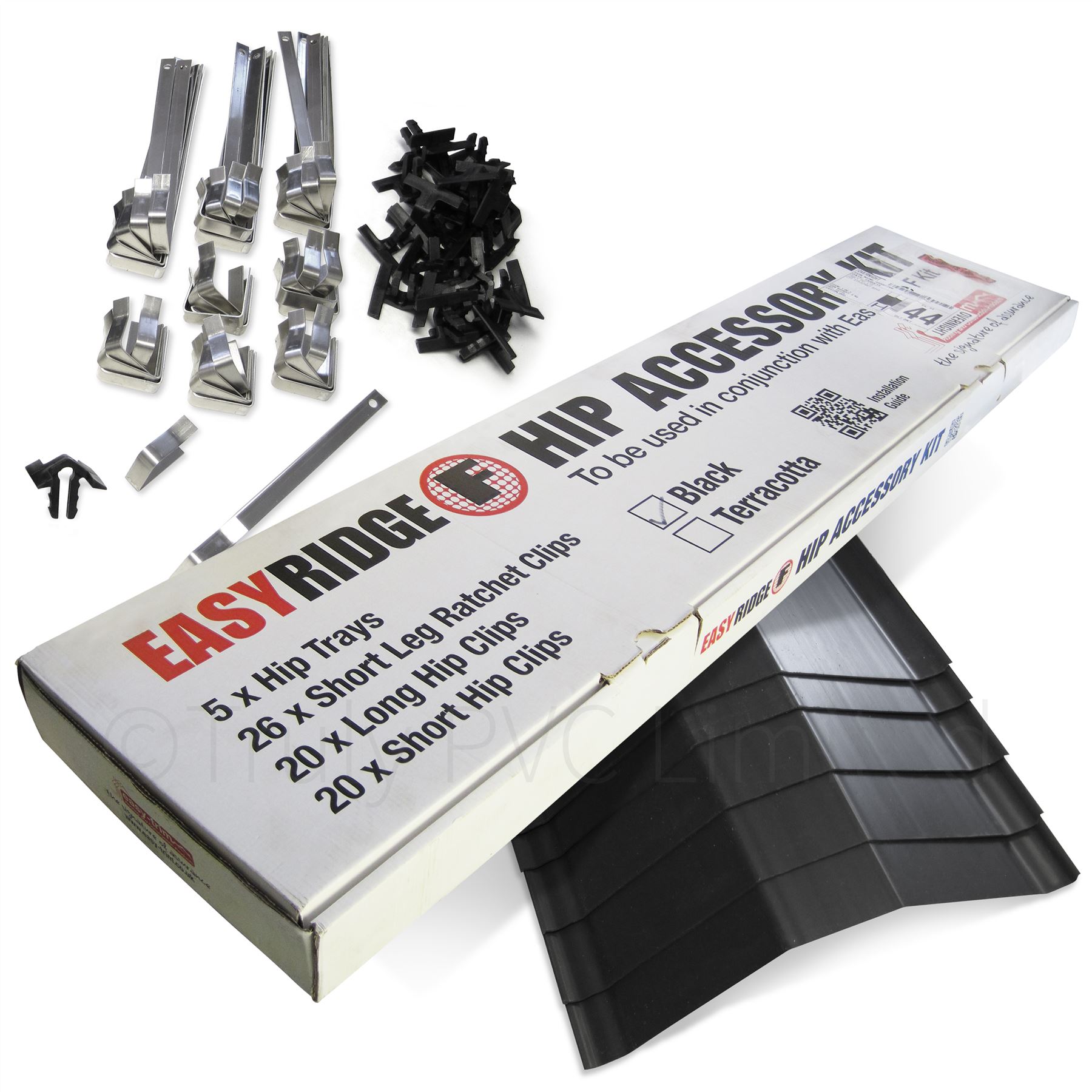

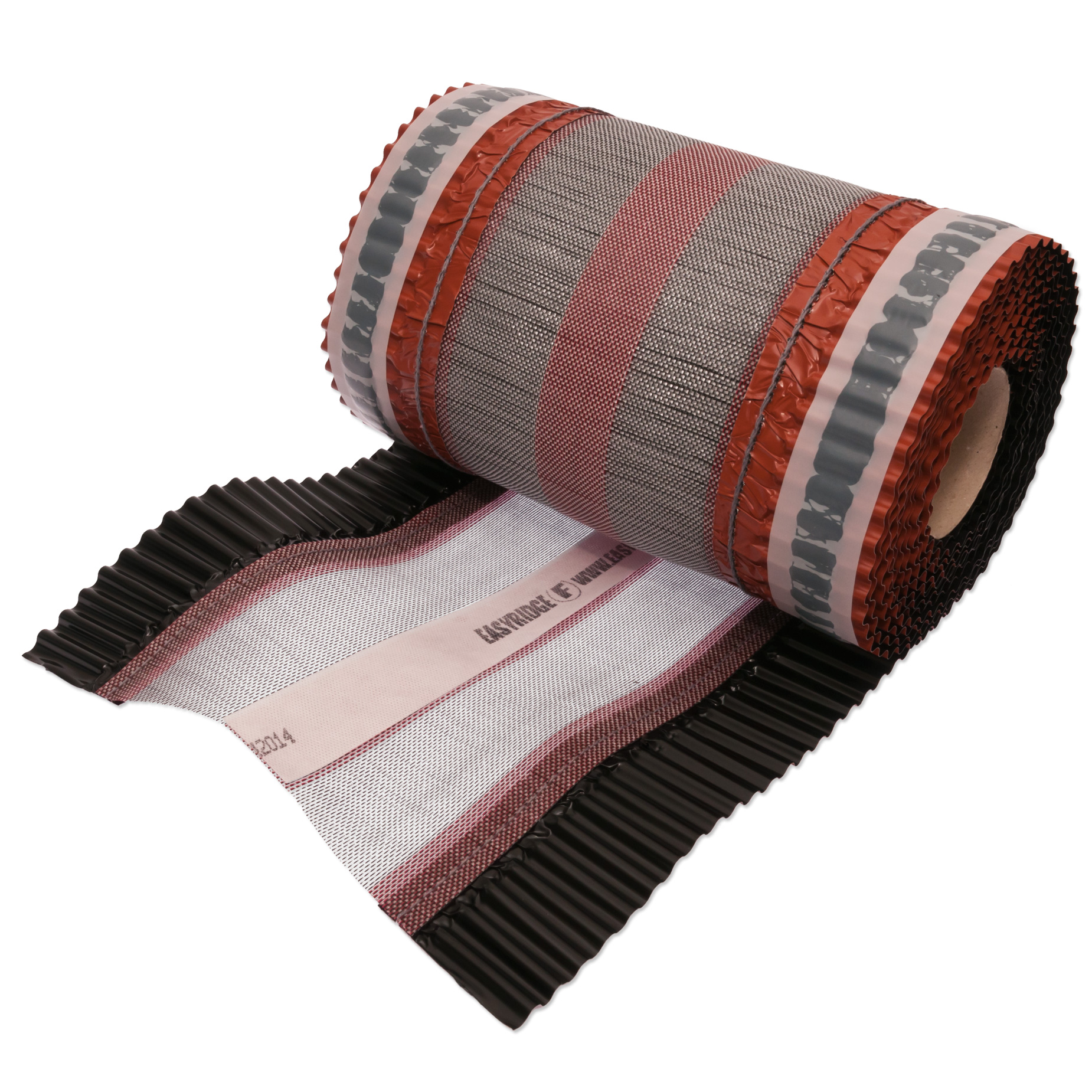

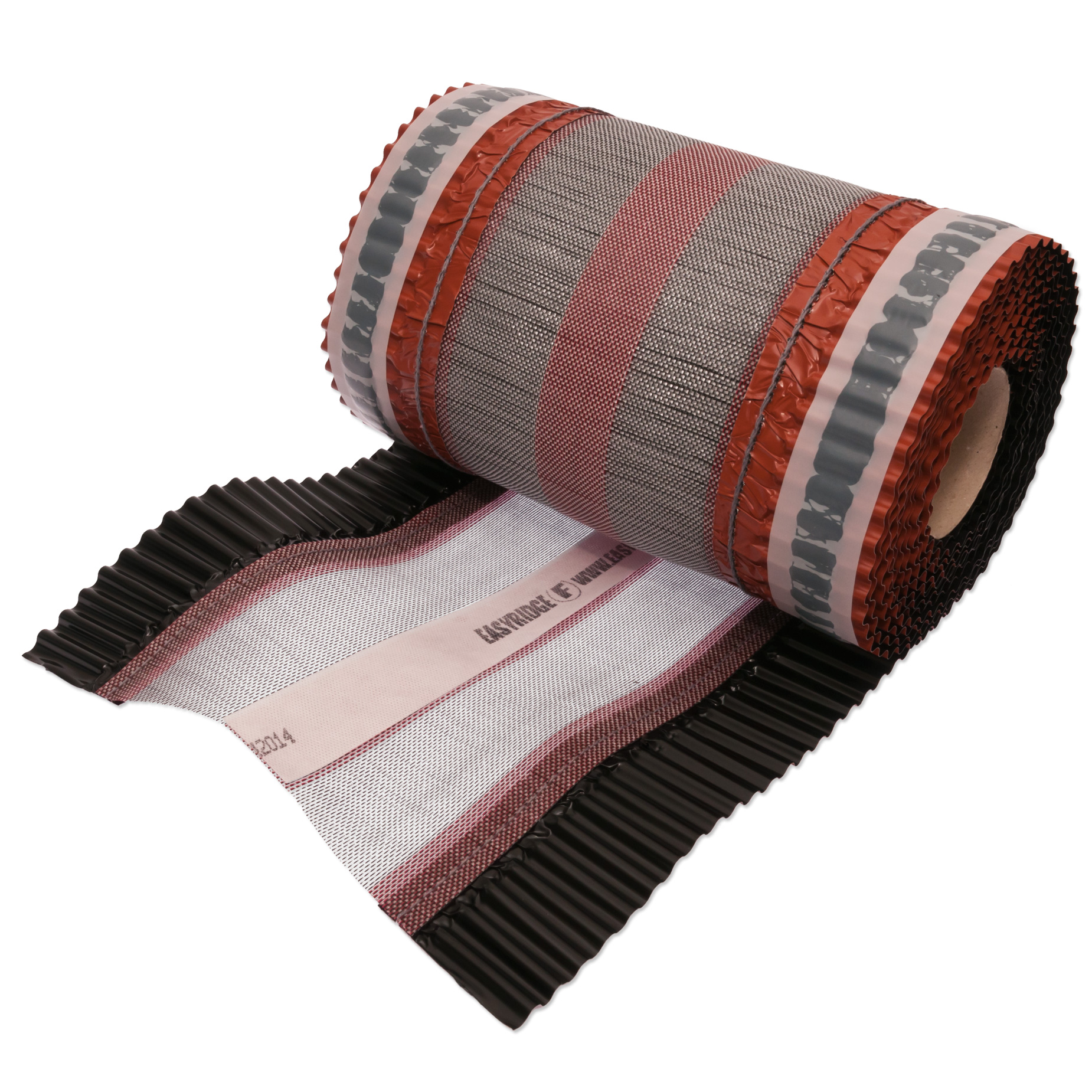

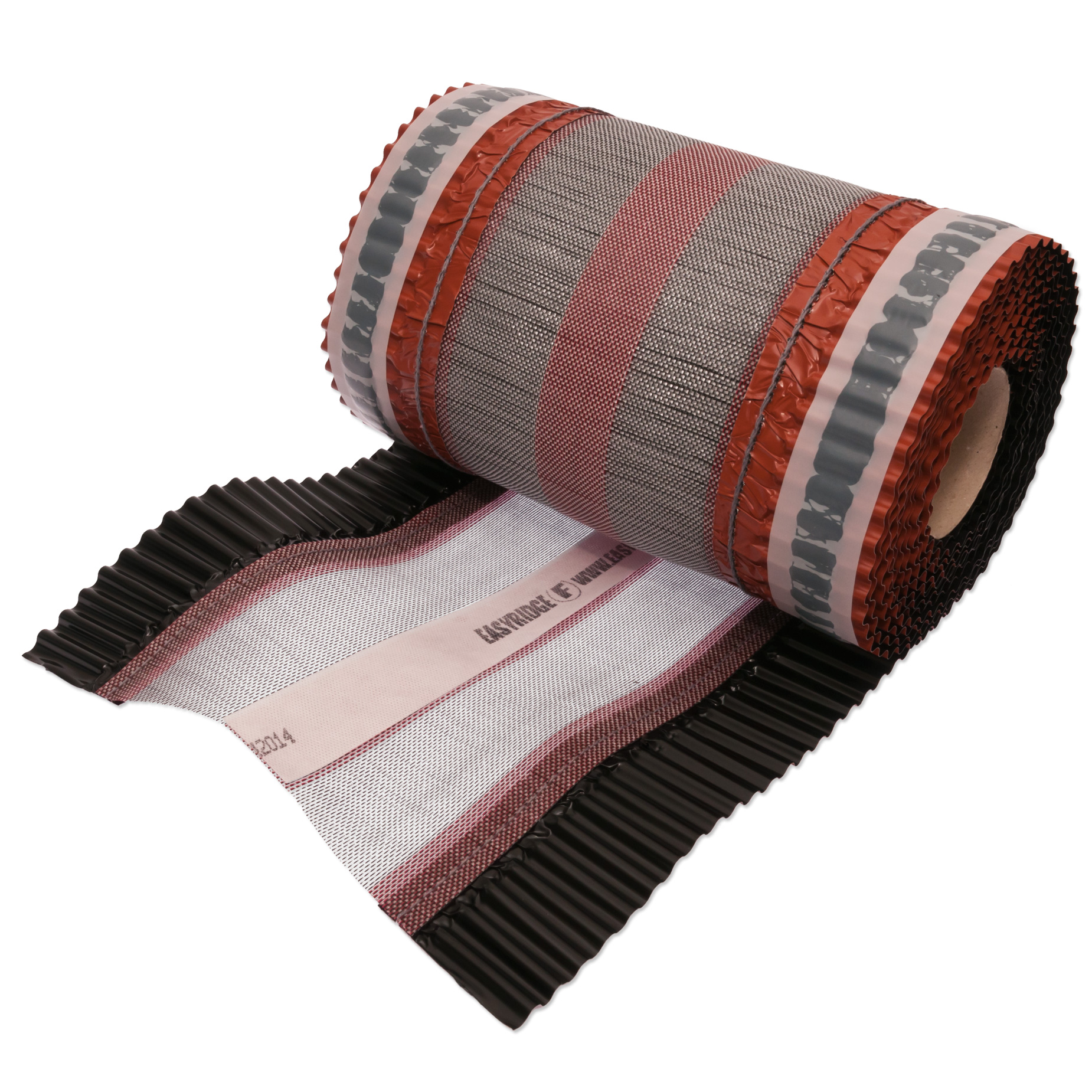

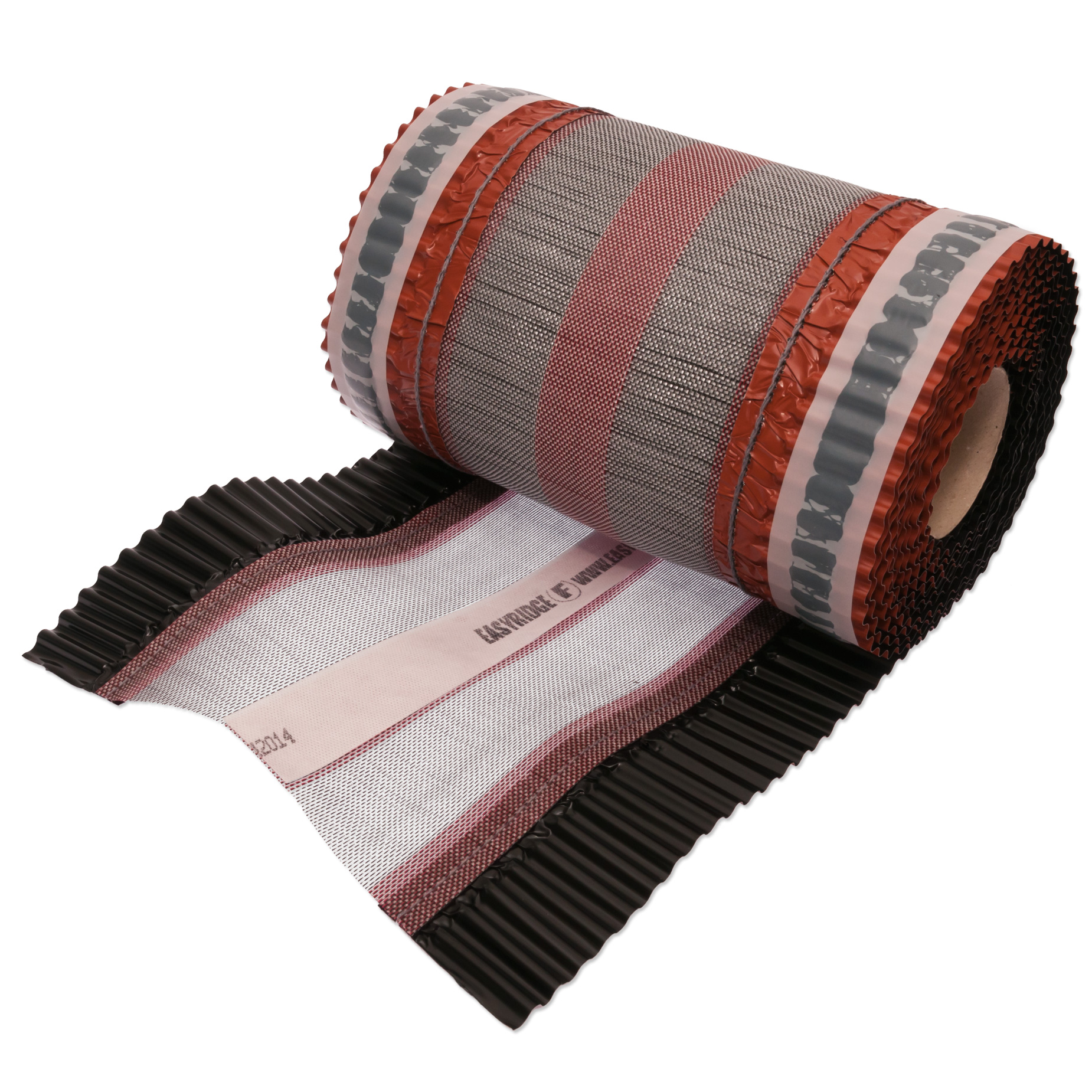

6m Ventilated Ridge Roll

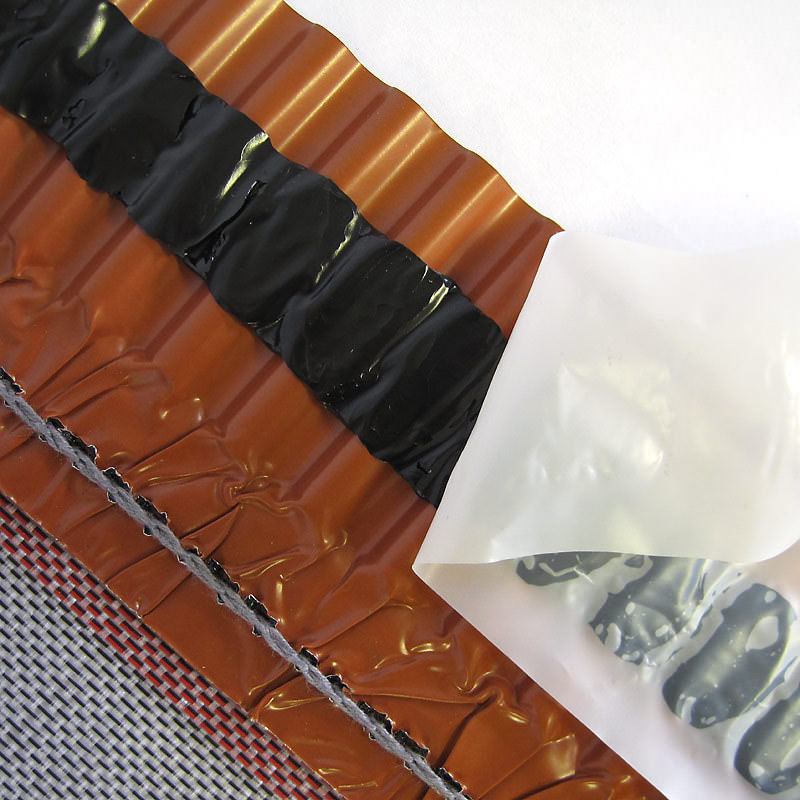

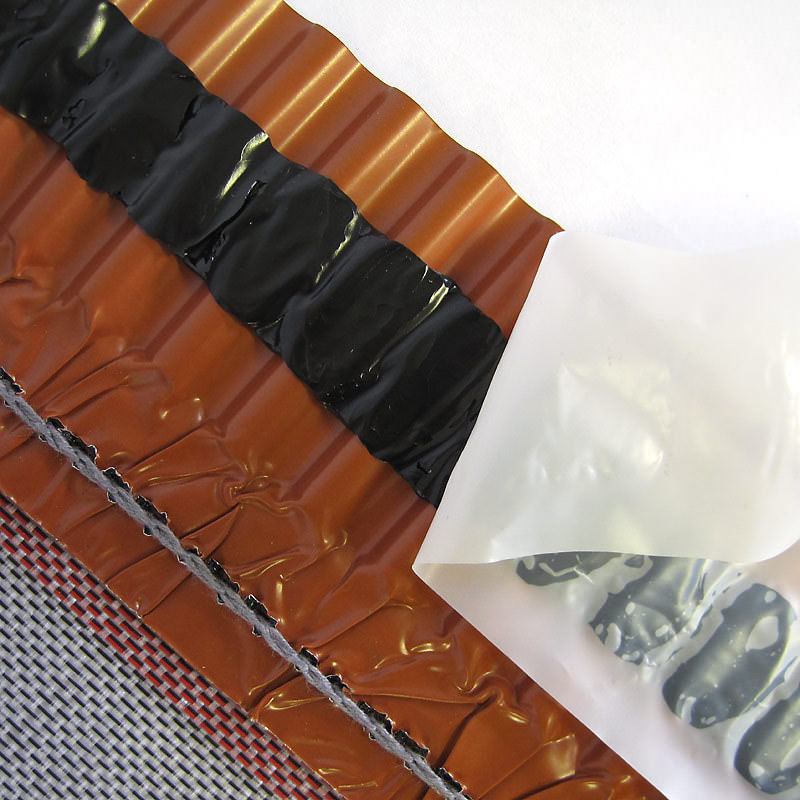

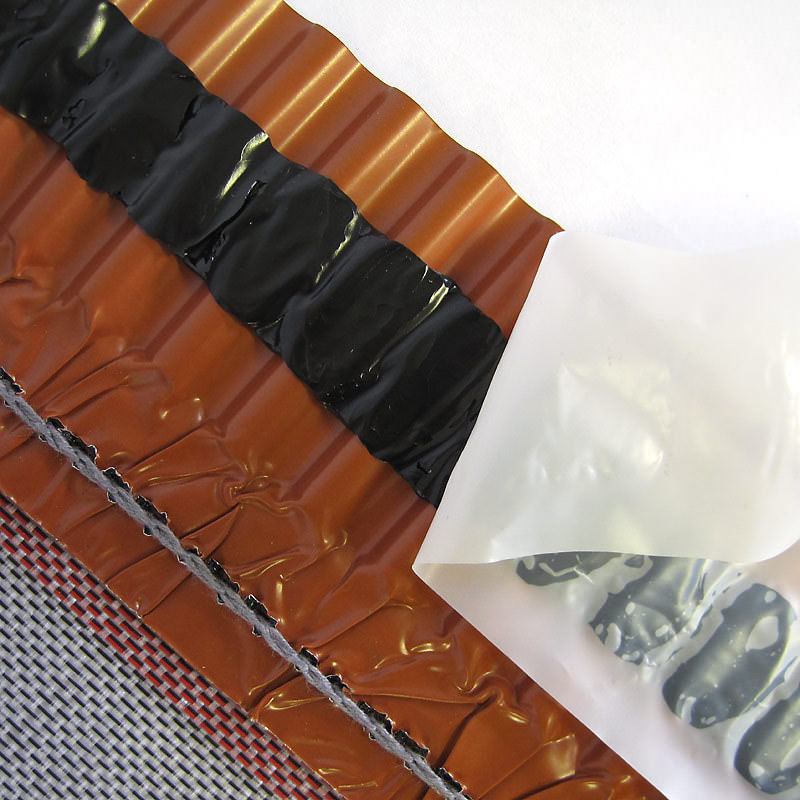

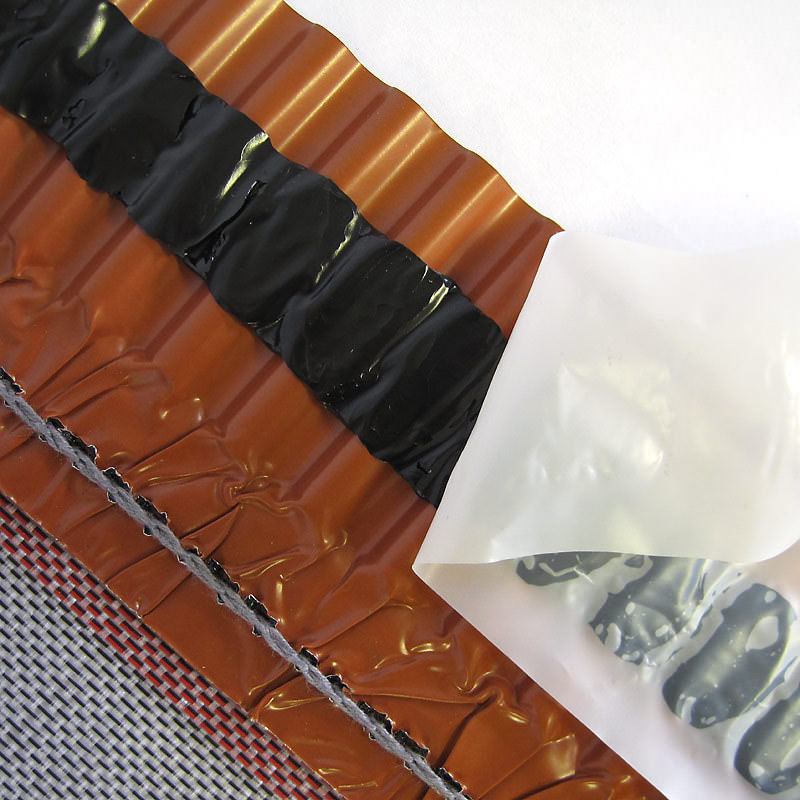

Polypropylene mesh fabric with spine and malleable crimped aluminium skirt, which makes it easy to dress over contoured tiles. Underside of skirt has high butyl adhesive strips for sealing against roof tile.

| Material | Polypropylene and Aluminium |

| Length | 6,000mm |

| Width | 300mm |

| Colour finge and clips | Black or Terracotta |

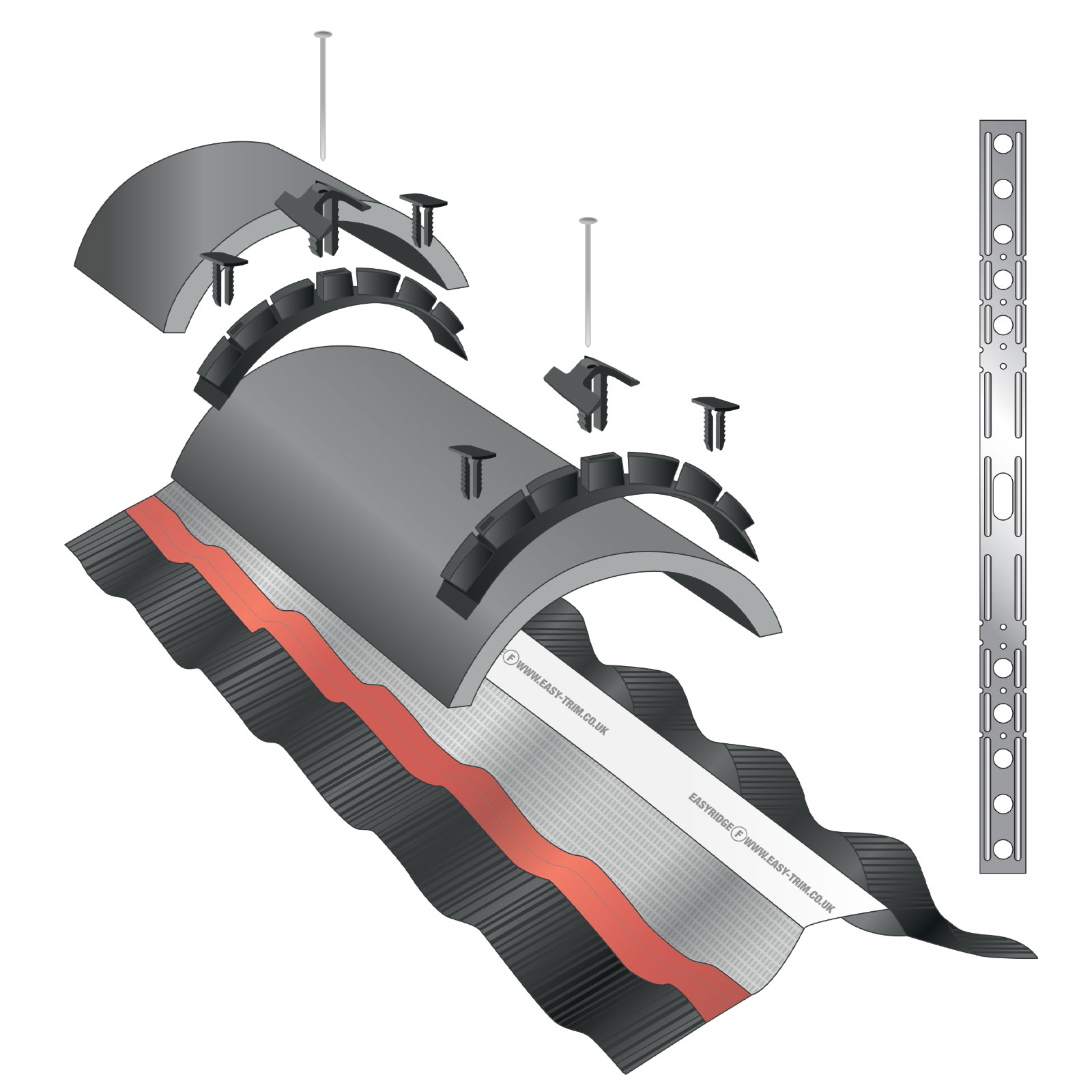

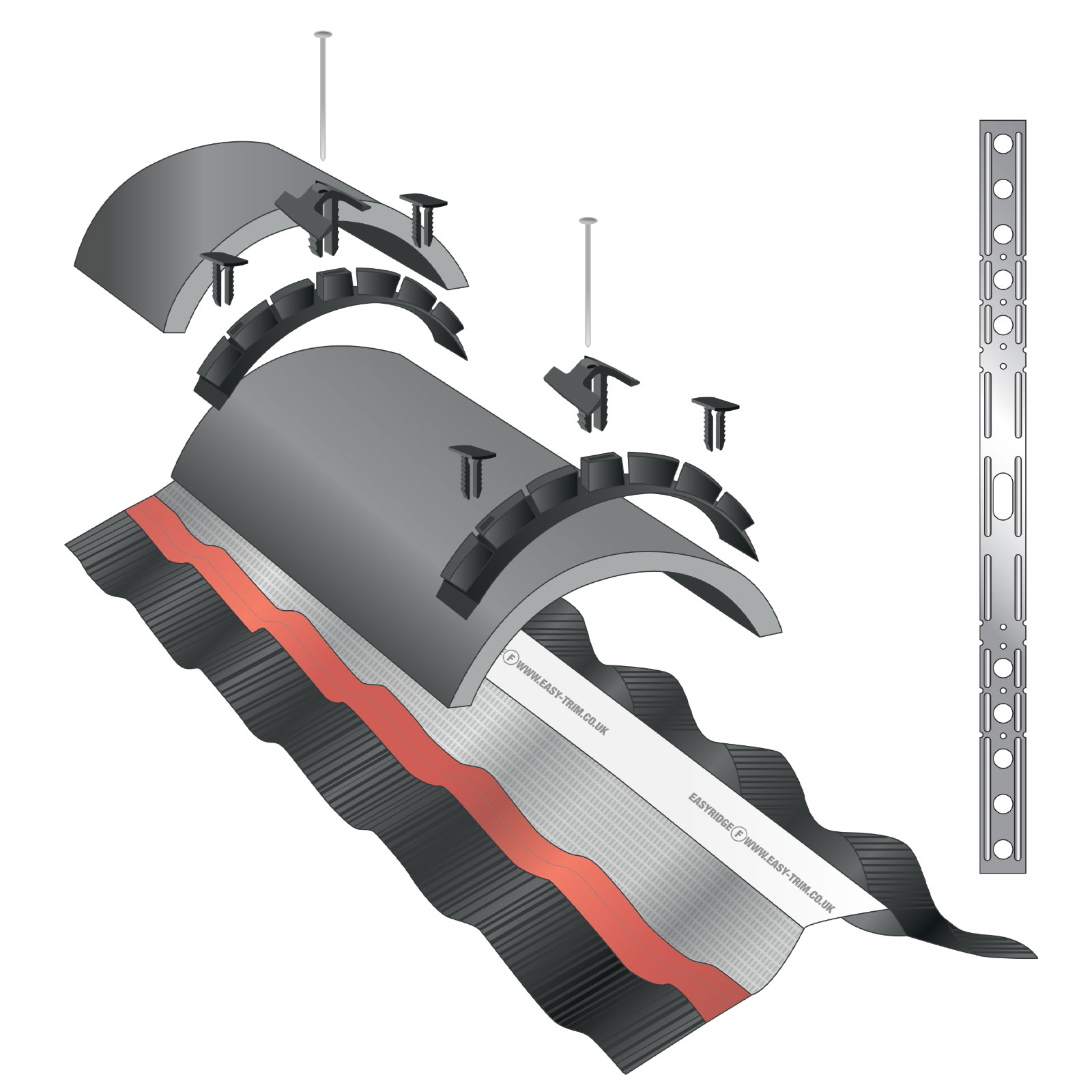

Ridge Unions (13 Pack)

Tough and flexible Nylon unions that you can use with almost all ridge tile, including angled and half round profiles of concrete or clay. Adjoining ridge tile sit on either side of a union up-stand and are trapped securely with 3 'ratchet' clips , the central one featuring a screw port to fasten to ridge batten with provided stainless steel screw. Enough unions are supplied for standard length ridge tiles over 6m. Additional unions may be required if ridge tiles are shorter than 400mm.

| Material | Nylon (union), Glass filled nylon (ratchet clips), Stainless Steel (screw fixings) |

| Length | 304.8mm |

| Width | 50mm |

| Height | 20mm |

| Colour | Black |

Each of the 13 x Unions is supplied with 1 x Large Ratchet Clip, 2 x Small Ratchet Clips and 1 x Stainless Steel screw.

* Measurements taken when union flat.

Ridge Batten Straps (10 Pack)

Stainless steel straps, designed to be folded over ridge fixing battens and nailed to roof truss rafters through pre-drilled holes. Supplied with approximately 45 x nails.

| Material | Stainless Steel (brackets), Stainless Steel (clout nails) |

| Strap Length | 400mm |

| Strap Width | 25mm |

Supplied with a quantity of Stainless Steel cloat nails.

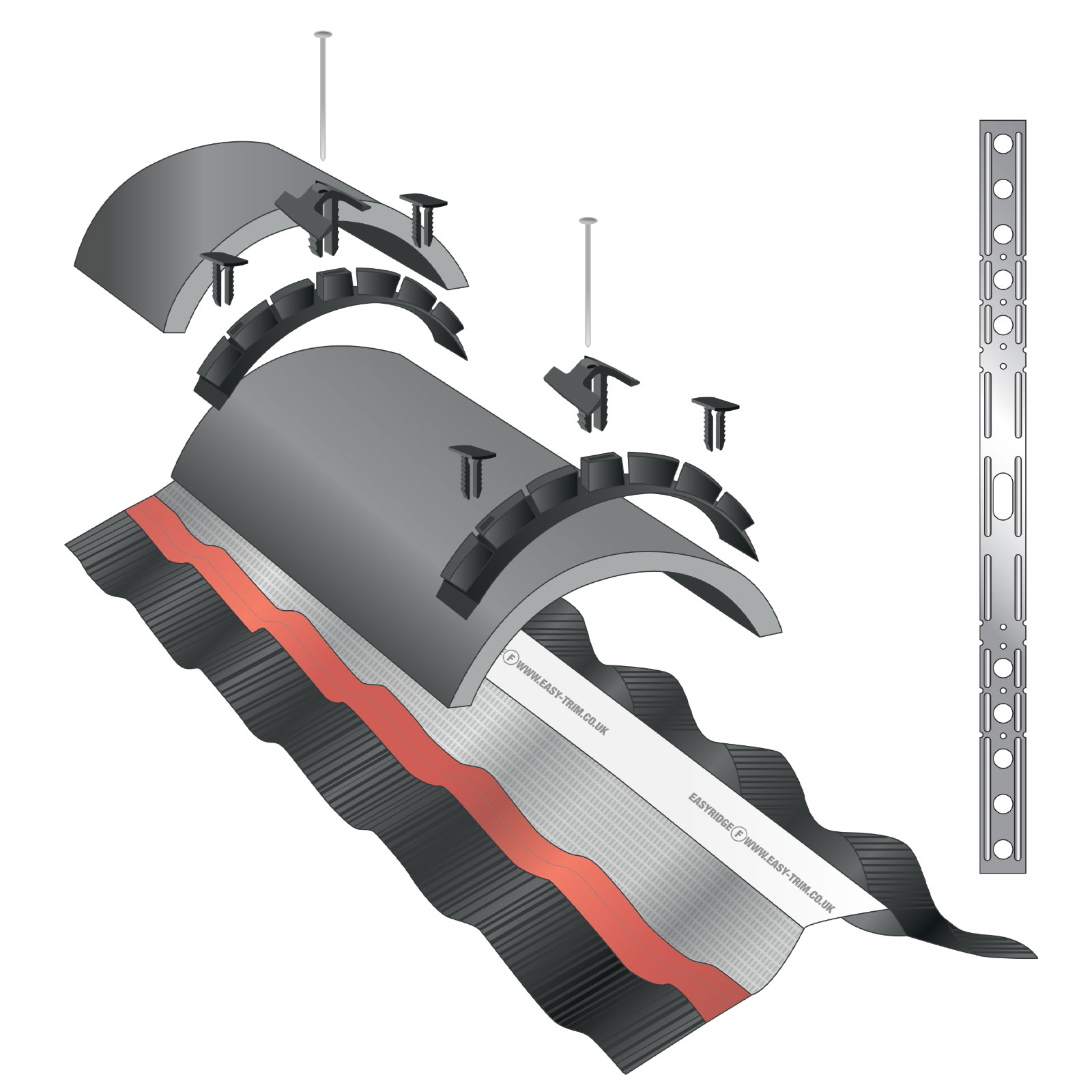

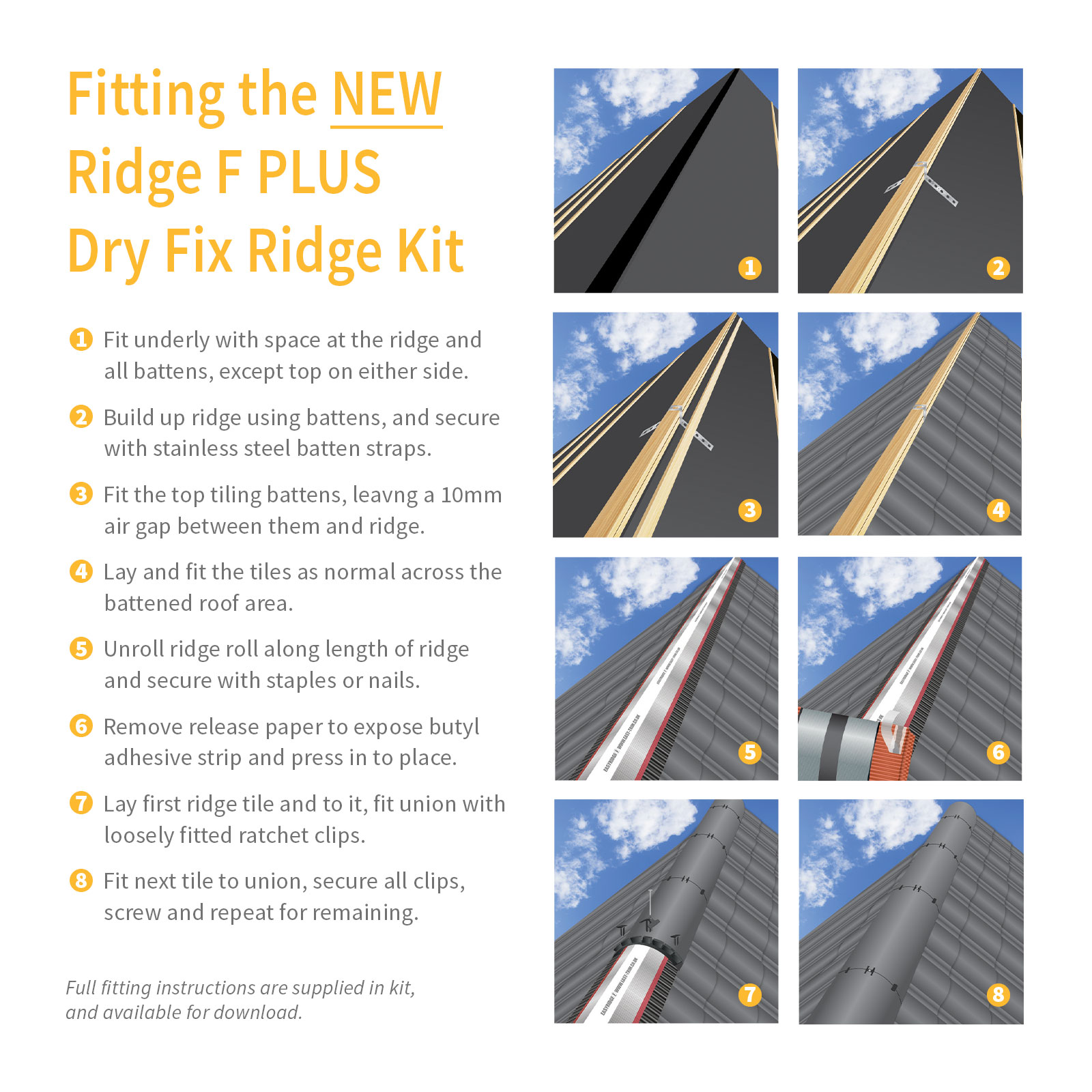

The kit is supplied with fitting instruction to help you through the process but be assured, fitting is quick and easy compared to mortar fitting and other dry-fix systems.

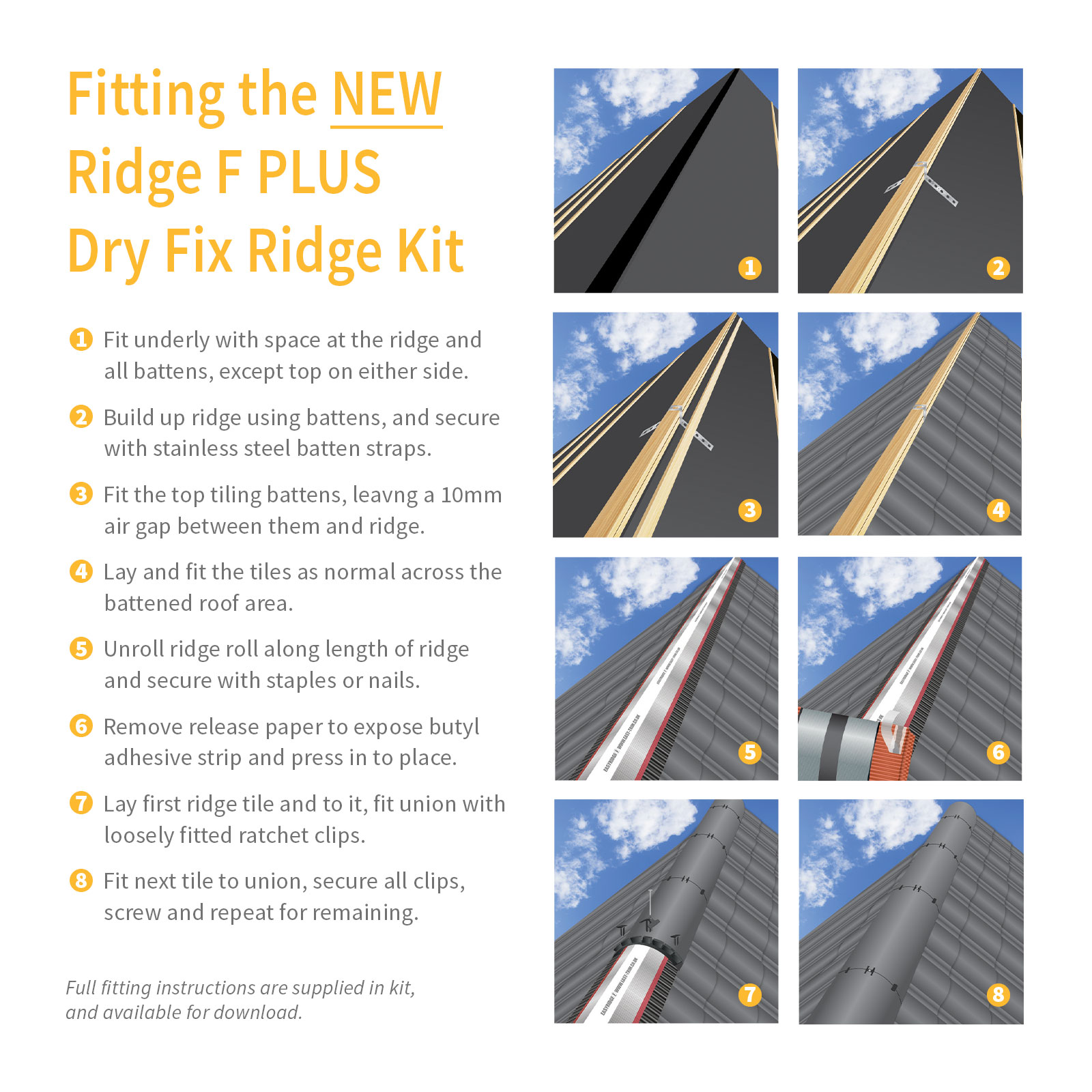

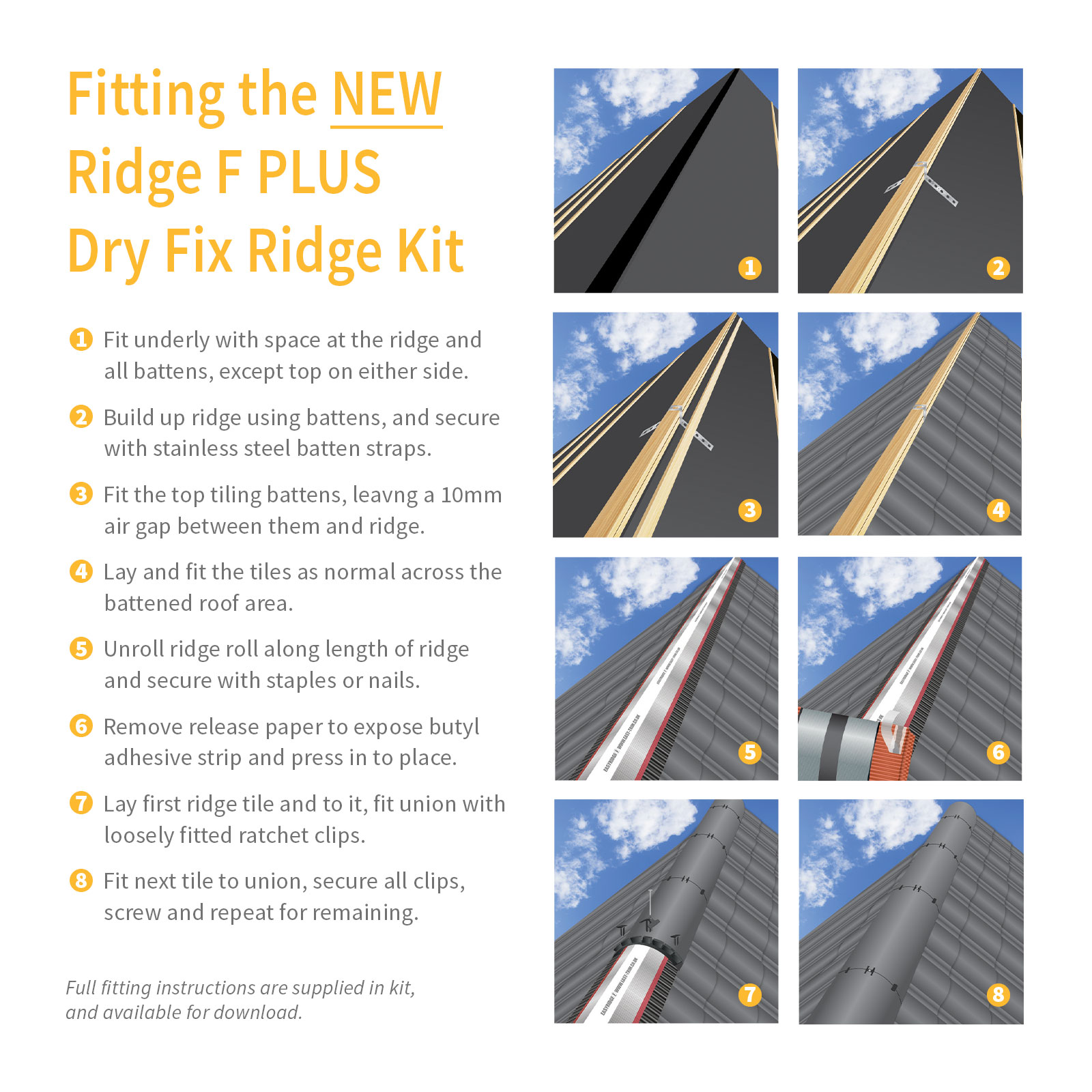

- Install roof underlay and battens as normal but finish underlay 5-30mm short of apex on either side and don't fit last batten

- Build up the ridge batten to required height (two battens are usually sufficient), and using stainless steel batten straps.

- Fix top tiling batten with minimum 10mm air gap between it and ridge batten, then lay and fix the tiles as normal

- Unroll EasyRidge F PLUS over the ridge batten, ensuring coverage over top course of tile and secure with corrosion resistant staples or nails

- Remove release paper from the butyl adhesive strips and dress neatly onto the dry/clean tiled surface

- Prepare the Unions by lightly pressing one large fixing clip (in the central slot) and 2 smaller ratchet clips

- Place end ridge tile and insert the prepared ridge union under and between the ridge tiles.

- Loosely tighten the 3 ratchet clips down onto the union.

- Secure to ridge fixing batten with Stainless Steel screw through central fixing clip

- Pushing the ratchet clips into the union to secure.

- Continue process along the ridge

0 of 0 reviews

Login

Accessory Items