ExtrudaSeal Smart Bifold Door Gasket

Replacement Gasket Seals for Smart Systems Bifold Doors

Stops draughts, heat-loss and leaks, quickly and easily!

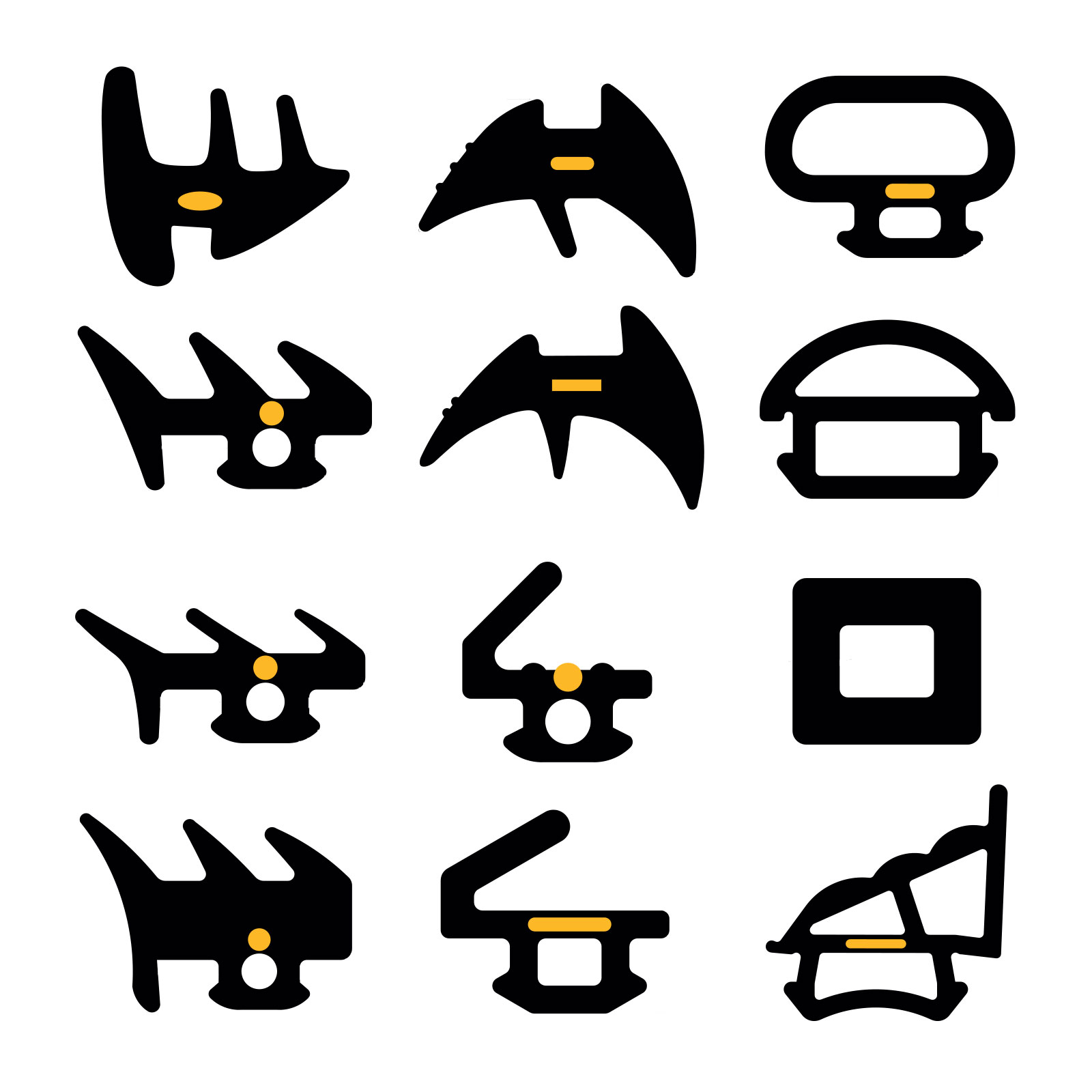

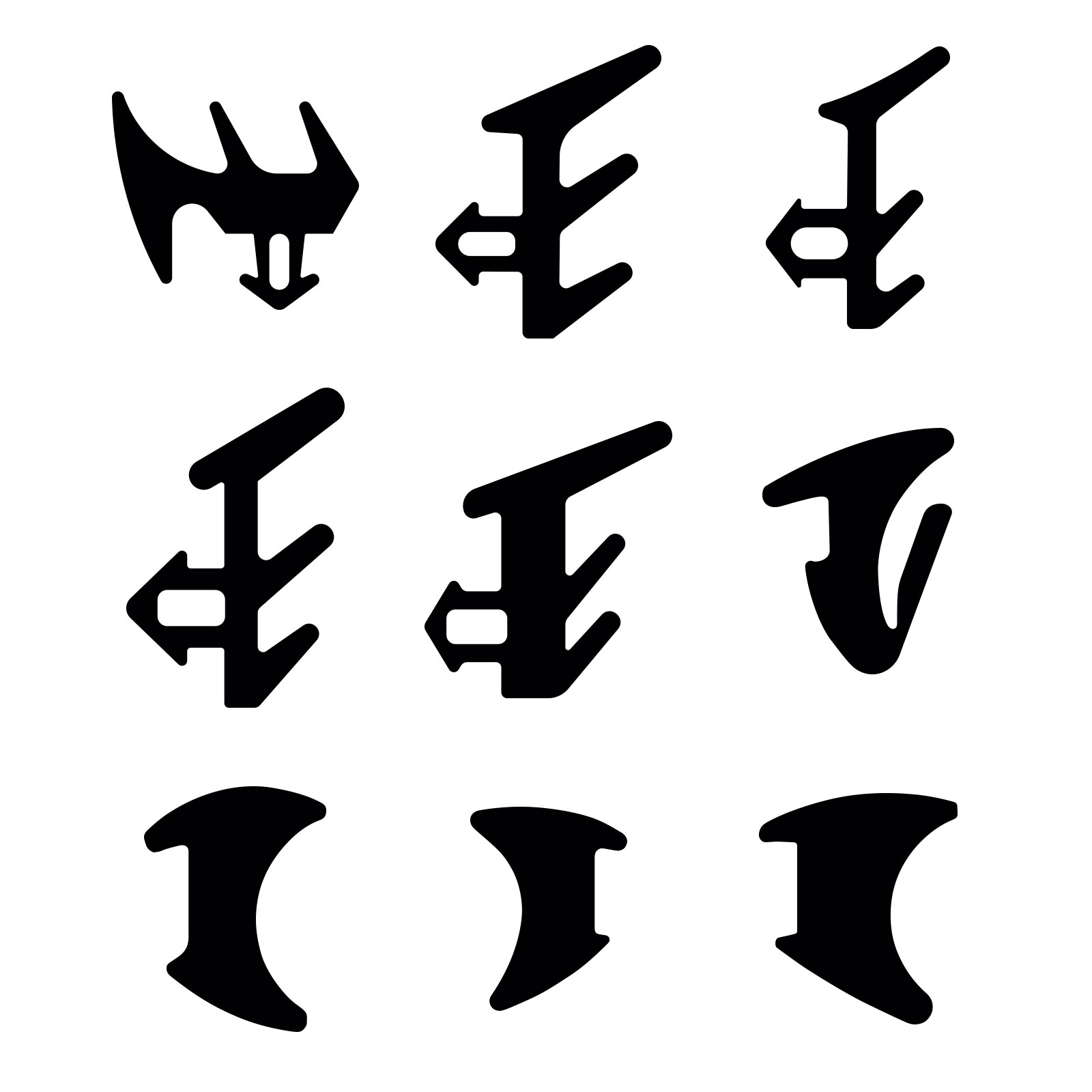

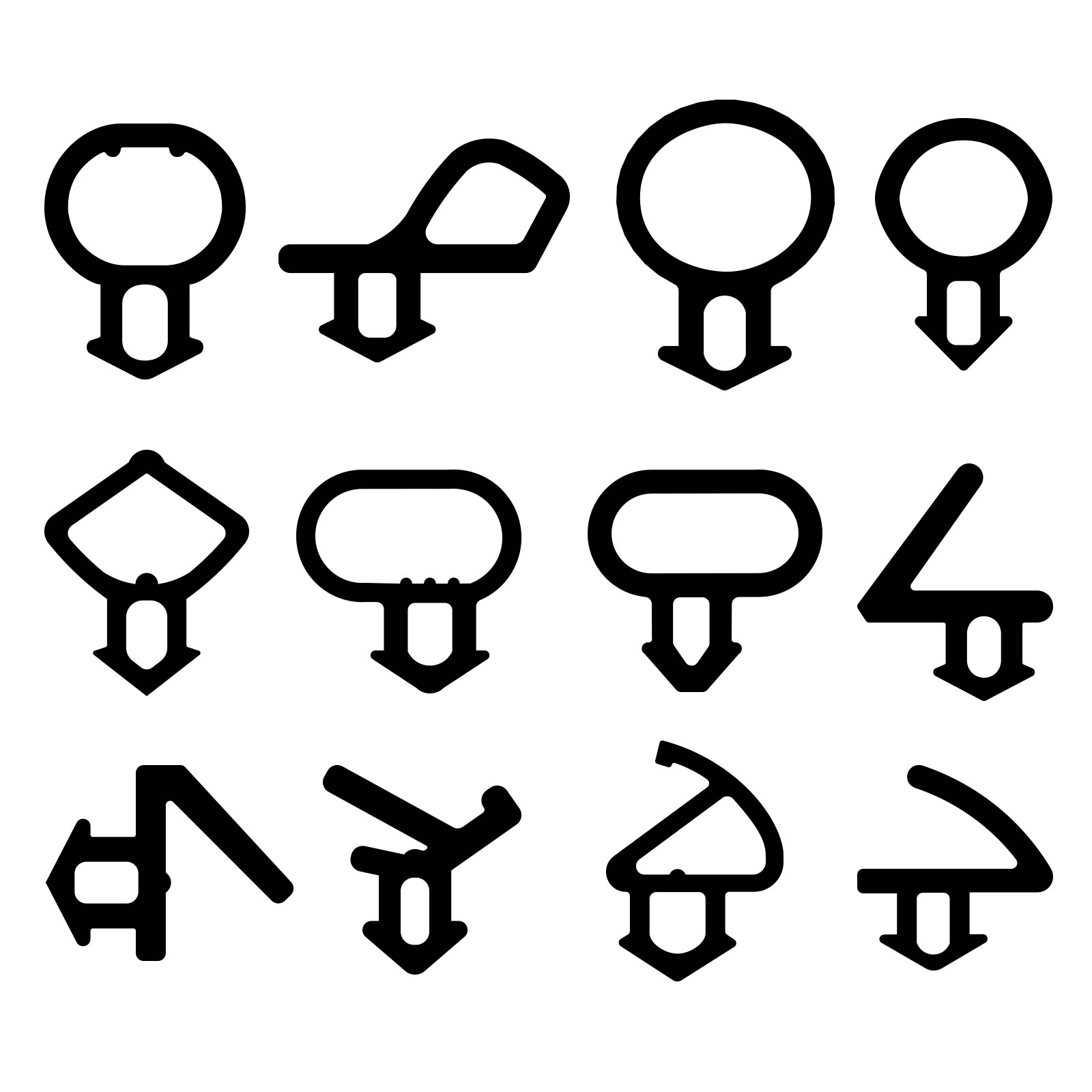

Replacement bubble, flipper, wedge and ’e’ gasket seals for sliding and folding bi-fold doors, including the Smart Visifold systems. Durable, high-quality material providing stretch and shrink resistance with long life performance.

Choice of gasket types includes bubble and flipper, for frame and sash use, plus wedge and ‘E’ gasket for sealing glazing within the sash.

Features & Benefits

- Quick and easy fitting - simply push into groove

- Smart system compatible - direct replacement

- New and improved - refined design and material

- Long life product - UV stability and anti-ageing

- Lower energy bills - helps reduce heat loss

- Low-cost solution - sold in various lengths

- Comfortable home - stop draught, noise and leaks

- Quality assurance - conforms to BS7412

Gasket may flatten over time or become damaged, and the rubber can become brittle, and shrink. All these things will affect the seal around the door, and likely lead to draughts, heat loss, water ingress and noise. Fitting new gasket is an easy, low-cost solution, that can seal your door like new, or even better, as some gaskets designs have been improved.

In this listing you can buy...

The following list summarises the bifold gaskets seals, for application and system compatibility, please see expanded tables under Technical Information.

PAE275 (ACDV272 Premium)

Premium sash/outer frame bubble gasket with zero-shrinkage nylon core.

AE272COR-ABC (ACDV275)

Set of four corner moulds (A, B, C, C) for use with PAE275 gasket on sash.

PAB633 (ACDV582 Premium)

Premium outer frame bubble gasket seal with zero-shrinkage nylon cord.

AB611 (VG52)

Small square gasket seal for use in the parallel tracks around outer frame.

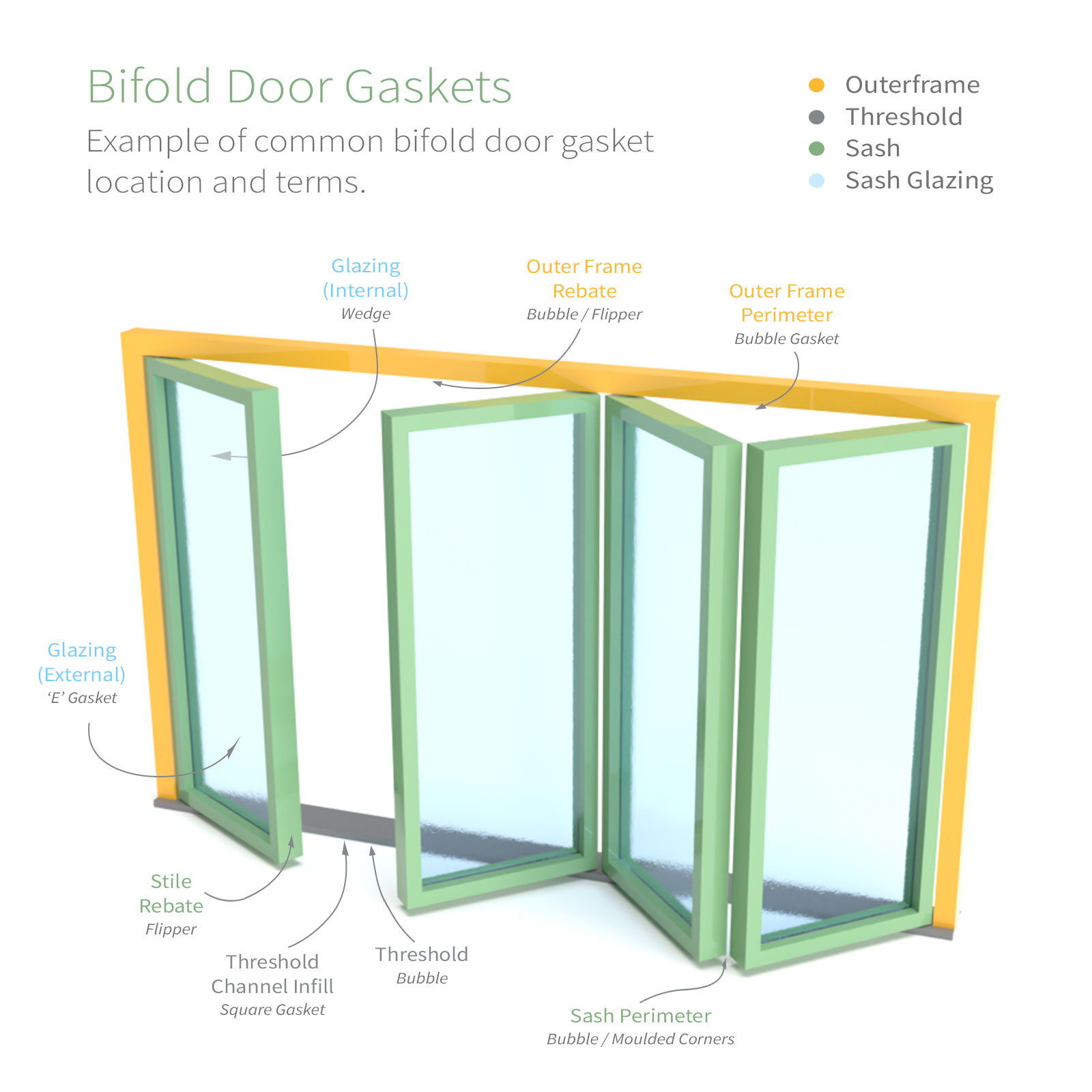

AF244 (ACDV244)

Flipper gasket for outer frame, which creates seal against closed door sash.

AB268 (ACDV268)

Outer frame bubble gasket offering enhanced weather performance seal.

AF032 (ACVL032)

Rubber flipper gasket for the effective sealing of doors with rebated stiles.

AE131 (ACVG131)

4mm E-type gasket for the external sealing of glazing in bifold door sash.

AE231 (ACVG231)

Small 2mm E-type gasket for external sealing of bifold door sash glazing.

AE031 (ACVG31)

3mm E-type gasket for the external sealing of glazing in bifold door sash.

AW033 (ACVG33)

Small 4mm wedge gasket for sealing inside of bifold door sash glazing.

AW034 (ACVG34)

5mm wedge gasket for the internal sealing of glazing in bifold door sash.

1863 (ACVG340)

6mm wedge gasket for the internal sealing of glazing in bifold door sash.

Technical information

Gasket Application

| Product Code | Gasket Type | Gasket Location | Application |

|---|---|---|---|

| PAE275 | Bubble | Sash | Perimeter, minus corners 1,2 |

| Outer Frame | Perimeter 1,2 | ||

| AE272COR-ABC | Bubble | Sash | Corners |

| PAB633 | Bubble | Outer Frame | Threshold 1,2 |

| AB611 | Square | Outer Frame | Channel Infill (Track), minus threshold |

| AF244 | Flipper | Outer Frame | Rebate 1,3 |

| AB268 | Bubble | Outer Frame | Rebate 1,3 |

| AF032 | Flipper | Sash | Stile Rebate |

| AE131 | E (4mm) | Sash | Glazing (External) |

| AE231 | E (2mm) | Sash | Glazing (External) |

| AE031 | E (3mm) | Sash | Glazing (External) |

| AW033 | Wedge (4mm) | Sash | Glazing (Internal) |

| AW034 | Wedge (5mm) | Sash | Glazing (Internal) |

| 1863 | Wedge (6mm) | Sash | Glazing (Internal) |

- Standard thresholds only. Low thresholds use/require a brushpile.

- PAB633 is often preferred to PA275 for use on threshold, as its crescent moon shape helps prevent gasket from being pulled out.

- AB268 is preferred to AF244 for enhanced weather performance, but can create too much friction for new installations.

Smart System Compatibility

| Product Code | Smart Code | Visifold System | Glazing Thickness |

|---|---|---|---|

| PAE275 | ACDV272 Premium 1 | 1000, 2000, 3000, 4000, 6000 | |

| AE272COR-ABC | ACDV275-A/B/C | 1000, 2000, 3000, 4000, 6000 | |

| PAB633 | ACDV582 Premium | 1000, 2000, 6000 | |

| AB611 | VG52 | 1000, 2000, 3000, 4000, 6000 | |

| AF244 | ACDV244 | 1000, 2000, 6000 | |

| AB268 | ACDV268 | 1000, 2000, 6000 | |

| AF032 | ACVL032 | 1000, 2000, 3000 | |

| AE131 | ACVG131 | 1000 | 24mm, 32mm, 34mm |

| AE231 | ACVG231 | 1000 | 38mm |

| AE031 | ACVG31 | 1000 | 28mm, 34mm, 36mm |

| 2000 | 28mm | ||

| 3000 (inward opening) | 24mm, 28mm | ||

| 4000 | |||

| AW033 | ACVG33 | 1000 | 34mm, 38mm |

| AW034 | ACVG34 | 1000 | 24mm, 28mm, 32mm, 36mm |

| 2000 | 28mm | ||

| 1863 | ACVG340 | 1000 | 34mm |

- Can be used in place of Smart ACDV202.

Material

| Product Code | Material |

|---|---|

| AB268 | PVC Nitrile with semi-rigid Polypropylene (PP) core |

| PAB633, PAE275 | PVC Nitrile with nylon core |

| AB611 | PVC Nitrile |

| AE025, AE131, AE231, AF032, AF244, AW033, AW034 | Thermoplastic Elastomers (TPE) with Polypropylene (PP) core |

Fitting Advice

Fitting bi-fold door bubble and flipper gasket

Bubble and Flipper compression seals are really easy to replace; just pull out the old, and after clearing away any debris from the gasket groove, push in the new. You should typically start top centre, and work round the sash or frame, whilst taking care not to stretch the gasket. If fitting PAE275 bubble gasket to a sash, the semi-rigid AE272COR-ABC corner moulds should be used, with the bubble gasket cross cut between them.

Fitting bi-fold door wedge and ‘E’ glazing gasket

Wedge gasket seals are normally fitted in four pieces for each edge of the glazing, with mitred ends for a neater seal. Replace one piece at a time, so that the beading on the other side and the glazing remain secure. Lever out the end of existing seal, and then remove the rest by hand. Take care to not damage the frame. Cut replacement wedge gasket 5% longer than measured, to allow for any shrinkage over time. To fit, just position one end tight into the corner and push down between frame and glass/panel along its length to the opposite corner.

‘E’ Gaskets clip into the frame, so usually require removal of beading and sometimes also the glazing. If glazing combines Wedge and ‘E’ gasket, then removing the Wedge gasket first will ease removal of the beading. Long beads will flex more than short beads, so remove those first. A fairly stiff wallpaper scraper can be used; just position half way along the bead, between bead and frame, and lever off. The first bead can be difficult, but the remaining beads will be easier. Take great care to avoid breaking beads, as sourcing replacement can be difficult. When putting beads back, start with the shorter beads, and finish with the longer ones. A rubber hammer can be used to knock the beads back into place.

Please note that many modern frames have coextruded gaskets, which are welded to the frame or bead. Some are welded to an old profile, which still has the gasket groove. In such a case, a replacement gasket can be fitted to the unused groove.

Login